1600 WIDE AREA MOWER

Wide-Area Mower

- Turbocharged diesel engine

- B20 compatible

- Rear-discharge decks

- FT4 engine compliant

View Product Brochure

Features

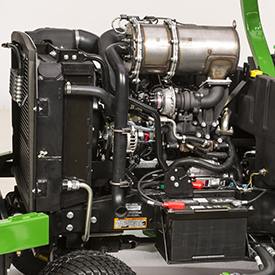

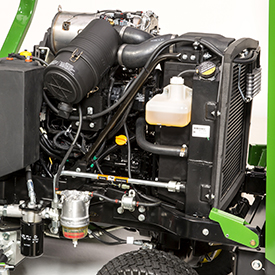

1600 Turbo Series III Wide-Area Mower (WAM) engine

1600 Turbo Series III Wide-Area Mower (WAM) engine 1600 Turbo Series III WAM engine

1600 Turbo Series III WAM engineThe 1600 Turbo Series III WAM is powered by a liquid-cooled, turbocharged, four-cylinder, 60-hp (44.7-kW) at 3000 rpm, PS diesel engine.

Engine features include:

- 117.3 lb-ft (159 Nm) of torque at 3000 rpm for extra lugging power on hills and in tough mowing conditions

- Large 127.6-cu in. (2.091-L) displacement, which produces the torque needed to handle hills and tough mowing conditions

Engine is a 16-valve (four valves per cylinder, two intake and two exhaust) design:

- Cold-start device to increase engine timing for improved cold starting

- Full-pressure lubrication for positive lubrication with continuous operation on slopes

- Dual-element air filter that is completely sealed for effective cleaning

Air filter with air-restriction indicator

Air filter with air-restriction indicator Air-restriction indicator

Air-restriction indicator- Progressive-type air-restriction indicator to let operator know when the filter needs servicing

- Automotive-type alternator (75 amp) that provides plenty of charge to the battery

- Glow plugs for quick starting in cold weather

- Automotive sensing system, which tells the operator when the engine is ready to start

- Isolated engine mounting, which reduces engine vibration in the operator's station for more comfortable operation

Direct fuel injection

- Injects fuel directly on top of pistons for more efficient combustion, less emissions

- Delivers more power per gallon of fuel

- Quicker starting and quieter operation

- Designed to meet California emission standards

- Features low levels of exhaust and emissions and excellent fuel economy. It meets the necessary Environmental Protection Agency (EPA) Tier 4 standard and meets 97/68/EC EU non-road mobile machinery (NRMM) emissions regulation

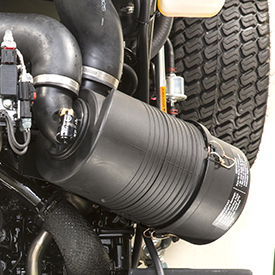

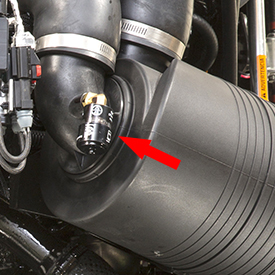

- Electronic engine control and cooled exhaust gas recirculation (EGR) system

- High-pressure common fuel rail for lower emissions and improved engine responsiveness

1600 Turbo Series III WAM side view

1600 Turbo Series III WAM side view Deluxe air-intake system

Deluxe air-intake system- Deluxe air-intake system

- Hood that is composed of a large, black, cross-link polyethylene-composite center section with green, metal side panels

- The composite center section includes air-intake screens and helps to guide the cooler air from above the machine to the radiator. The design provides a uniform distribution of clean air, as well as minimizing the amount of chaff collection on the exterior screens.

- Additional sealing around the operator station reduces the amount of hot air blowing on the operator, which in turn improves operator comfort.

- The rear bumper helps with hood sealing and reduces the potential for rear hood damage.

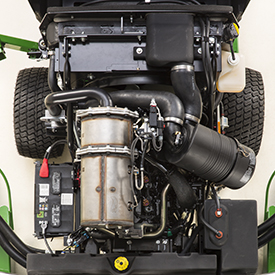

Flow of exhaust during engine operation

- Exhaust airflow enters into the EGR cooler from the exhaust manifold near the turbocharger

- Cooler takes hot exhaust gases and cools them to where the temperature will not have excessive impact on combustion efficiency

- Based on load, air temperatures, and rpm, the engine control unit (ECU) opens (or closes) the EGR valve, allowing exhaust gases into the intake manifold. The gases mix with the rest of the incoming air from the turbocharger and aftercooler.

Other engine features:

- Overhead valve (OHV) for efficient combustion

- Liquid-cooled for more consistent operating temperatures

- Closed crankcase ventilation that burns crankcase hydro-carbon evaporation

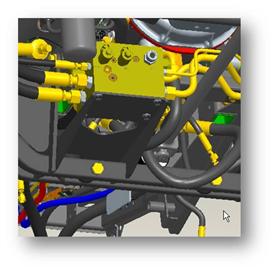

Hydrostatic transmission

Hydrostatic transmissionA hydrostatic transmission is used for reliable operation.

Durability features include:

- Large, forged, one-piece trunnion shaft with large support bearings to reduce vibration and noise

- Charge pump used to efficiently deliver oil to the transmission

- Oil cooler to cool transmission oil for longer transmission life

- Pressure-side filtration to allow use of a finer mesh (10 micron filter) than suction filtration systems

High-range/low-range transaxle allows the following:

- High range has maximum speed of 15 mph (24.1 km/h) for faster transport. Power take-off (PTO) can be engaged for mowing in high range.

- Low range has a maximum speed of 9 mph (14.5 km/h). The wide-area mower (WAM) can mow in both low and high range.

Differential lock

Differential lockThe differential lock is standard equipment:

- It locks both the front drive wheels together for extra traction, when needed.

- Conveniently located pedal allows the operator to engage the differential lock.

Air-intake system

Air-intake system High-capacity cooling system

High-capacity cooling systemAn innovative, exclusive air-intake system draws clean air from the top of the machine instead of the rear. This keeps the radiator cleaner and prevents the engine from overheating.

The high-capacity cooling system combines the radiator and hydraulic oil cooler.

Control console

Control consoleLow-effort controls are conveniently grouped on the right-hand side.

The finger-touch controls are:

- Left mower deck lift/lower switch

- Front mower deck lift/lower switch

- Right mower deck lift/lower switch

- Electronically-controlled throttle lever

- Electronically-activated power take-off (PTO) switch

- Speed-range lever for high, neutral, and low range

- Four-wheel drive (4WD) lever

Hydrostatic power steering

- Makes it easy to turn the machine, reducing operator fatigue

- Allows quick steering action, two and a half turns lock-to-lock, for excellent maneuverability

Two-pedal foot controls

Two-pedal foot controls

Two-pedal foot controls - Convenient two-pedal hydrostatic control system

- Allows the operator to select speed and direction with just a touch of the toe while resting heel on platform

- Twin Touch™ pedal design that allows the operator to change direction without having to lift his foot off the platform

- Large pedal surface, which provides increased operator comfort

- Keeps both hands free for steering and operating controls

Standard turning brakes

Standard turning brakes

Standard turning brakesThe individual brakes can be applied by the operator as a traction aid or to reduce the turning radius.

Master stop brake

Master stop brake

Master stop brake- Brake is easy to use.

- Push-pull-type parking brake release allows the operator to simply pull out the knob and depress the foot brake to engage. To disengage, simply push the foot brake pedal and push the knob in to initiate release.

- Brake provides stopping power to both drive wheels.

- The stop brake is used for a parking brake.

Differential lock

Differential lock

Differential lock- Locks both front drive wheels together for added traction

- Increases traction and flotation in poor traction conditions

The differential lock is located on the left side of the platform; this allows for easy use of the Twin Touch foot pedals (on the right side) while engaging the differential lock at the same time.

High/low range lever

High-/low range lever

High-/low range lever- The high-/low range lever allows the operator to select the desired speed range.

- The machine must be stopped to shift between ranges.

- Shifting to the neutral position allows the operator to by-pass the hydraulic drive for towing.

4WD lever

4WD lever

4WD lever- The 4WD lever allows the operator to engage 4WD in reverse. 4WD is automatically engaged when wheel slip occurs in forward drive.

Electronic cruise control

Electronic cruise control

Electronic cruise control- Beneficial when mowing open areas or when transporting

- Located on the steering column

Cruise control operation

- To engage, simply push forward on the cruise control switch and hold until the foot is removed from the forward pedal.

- For an emergency stop, cruise can be released by pushing on the master brake pedal or turning the cruise control switch off.

Mower deck lift switches

Mower deck lift switches

Mower deck lift switchesThe mower deck switches allow the operator to vary mowing widths, engage and disengage the wing-deck blades, and service and transport the machine.

Tilt steering

Tilt steering

Tilt steering Headlights

Headlights- Allows the operator to adjust the steering column to the most comfortable position and provides additional clearance for entry to the operator station

- Standard 20-W halogen headlights are located low in the column for the best illumination

High-back, air-ride seat

High-back, air-ride seatAn air-ride suspension seat is standard equipment and provides maximum operator comfort across a wide range of operator traits. Key adjustments include the following:

- Weight and height adjustment allow for proper ride and suspension height.

- Fore-aft sear slide adjustment helps account for a wide range of heights.

- Fore-aft suspension travel to improve directional changes during operation.

- Back angle tilt adjustment is available for the back portion of the seat.

- Lumbar adjustment provides proper back support.

- Standard, adjustable armrests are made of a durable material that provides adequate support and surface area for the operator's arms.

- High seat-back profile features body-contoured seat cushions.

- Cushions are ideal for those who seek proper back support. The highly-resilient contoured foam construction allows for all-day mowing comfort.

- A raised seat ensures a commanding view to the front and side mower decks.

- The retractable seat belt is convenient to use.

The comfortable seat, along with ample legroom in the operator's platform, convenient pedal locations, and adjustable steering column make operator comfort on the John Deere 1600 Turbo Wide-Area Mower among the best in the industry.

The standard air-ride seat with adjustable armrests is designed with comfort, safety, and ergonomics in mind, ensuring relaxed, healthy sitting for hours on end.

The standard high-back, air-ride seat has many high-quality features:

Fore-aft lever

Fore-aft lever- Adjustments are provided for operator armrests, lumbar support, and back angle, and air suspension is adjustable for the operator’s weight and ride.

Armrest adjustment

Armrest adjustment Air-ride seat adjustment

Air-ride seat adjustment Back-angle adjustment

Back-angle adjustmentThe armrests are standard and the seat pads are replaceable.

Two-post Roll-Gard ROPS

Two-post Roll-Gard ROPS ROPS folded down for clearance

ROPS folded down for clearanceThe two-post folding Roll-Gard ROPS and seat belt are standard equipment:

- When used in combination with seat belts and safe operating practices, the ROPS is effective in reducing serious injuries and death from rollover accidents.

The standard-equipment Roll-Gard ROPS can be folded to allow for additional clearance when needed. With the ROPS in the folded-down position, the machine fits under a standard doorway.

The ROPS meets the International Organization for Standardization (ISO) 21299 ROPS standard – defined test procedures and acceptance criteria for the rollover protective structures of powered ride-on turf care machinery. Under the support of the Outdoor Power Equipment Institute (OPEI), a panel was formed that brought together an international group of ROPS experts that presented the best-learned practices regarding off-highway vehicle operator crush protection. The result of this undertaking is a standard dedicated to protecting operators of powered ride-on turf maintenance equipment.

The ROPS can be folded down without tools for operation under tree canopies or in other confined operating spaces. Operators should leave the ROPS in the upright position for all other mowing:

- The folding ROPS enhances operator safety and still provides clearance when loading on enclosed trailers.

Folding the ROPS is simple - remove two pins and rotate the top of the Roll-Gard ROPS down. Adjustments can be made from the operator's station.

The folding ROPS performance is certified at the date of manufacture, per the following standard:

- ISO 21299

Four-post ROPS

Four-post ROPS Four-post ROPS side view

Four-post ROPS side viewDue to the high percentage of operators who prefer the four-post ROPS canopy, a factory-installed option is available. The rear ROPS structure is a black fixed two-post ROPS.

The ROPS comes standard with a canopy and assembles to the 1600 Turbo Series III Wide-Area Mower (WAM) along with a two-post

Roll-Gard™ ROPS.

The four-post ROPS structure includes the following:

- Two front posts

- Rear ROPS

- Welded top and bottom assemblies

- Molded canopy

The four-post ROPS provides the ability to meet bid requirements that call for a four-post ROPS and offers the ability to use a weather enclosure. It also meets the International Organization for Standardization (ISO) 21299 standard.

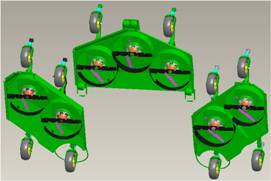

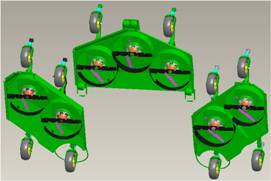

Wing decks raised

Wing decks raisedThe wing decks rise to a narrow 84-in. (213.4-cm) width and can be locked into transport position. A machine transport speed of 15 mph (24.1 km/h) means the operator can spend less time transporting and more time mowing.

NOTE: The power take-off (PTO) can be engaged while in the transport position.

Proper trailering strap areas

Fasten the machine to the trailer with heavy-duty straps, chains, or cables. Fasten the rear strap to the tow loop behind the rear axle. Fasten the front strap to tie down holes on the operator's platform. Both the front and rear straps must be directed down and outward from the machine.

Bumper

Rear bumper

Rear bumperThe rear, frame-mounted bumper provides for excellent rear protection and effective hood sealing for engine cooling.

To operate, pull out on the bottom of the engine cover latches on the left and right side of machine behind the operator’s seat. Unhook the tops of the engine cover latches from the hooks on the engine cover. Push down on the bumper lever and rotate the bumper to the right side of the machine.

Rear bumper latch in locked position

Rear bumper latch in locked position Rear bumper latch in unlocked position

Rear bumper latch in unlocked position Rear bumper in open position

Rear bumper in open position Engine cover open

Engine cover open Wide-area mower (WAM) top view

Wide-area mower (WAM) top view WAM front view with side mowers raised

WAM front view with side mowers raised 128 in. (325.1 cm) with both wings down

128 in. (325.1 cm) with both wings down 94 in. (238.8 cm) with center deck and either side deck down

94 in. (238.8 cm) with center deck and either side deck down Front and side mowing

Front and side mowing 62 in. (157.5 cm) with center deck only

62 in. (157.5 cm) with center deck onlyThe 1600 Turbo Series III WAM is equipped with a 62-in. (157.5-cm) center deck and two 42-in. (106.7-cm) wings. Cutting widths are 128 in. (325.1 cm) using all three decks, 94 in. (238.8 cm) using the center deck and either wing deck, and 62 in. (157.5 cm) with the center deck only. All decks are rear discharge. Wings fold for transport and reduce the machine’s width to a narrow 84 in. (213 cm), so it can easily be driven along golf-cart-size paths or fit on a trailer. The wing decks will float 45 degrees above horizontal and 20 degrees below horizontal, following the ground contour.

Underside of 62-in. (157.5-cm) deck

Underside of 62-in. (157.5-cm) deck Side view of 42-in. (106.7-cm) deck

Side view of 42-in. (106.7-cm) deckAll decks have a unique baffling system that reduces clumping and provides even clipping dispersal for exceptional appearance.

Features common to these rear-discharge mower decks include:

- Mower decks are fabricated from 7-gauge, 0.179-in. (4.6-mm) steel, the thickest in the industry; strength has been designed into the 1600 Turbo Series III WAM mower decks for increased reliability

- A 3/4-in. (1.9-cm) solid bar runs along the entire mower deck perimeter for added strength

- Dual-range height of cut spans 1 in. (2.54 cm) to 5.5 in. (14 cm) in 0.5-in. (1.27-cm) increment adjustments

- Wing deck float of 45 degrees upward and 20 degrees downward provides excellent cut quality when mowing undulating terrain

- Each wing deck has four caster wheels to follow ground contour and provide unmatched cut quality

- Unique baffling system produces even grass dispersal for superior appearance

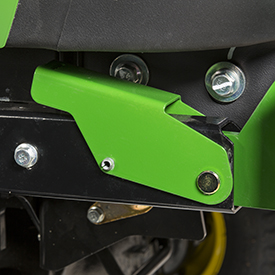

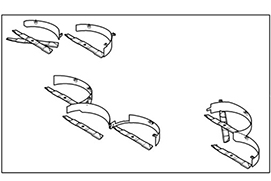

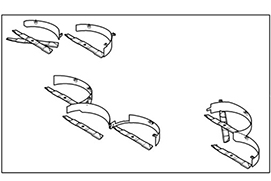

Patented impact-absorbing system

Patented impact-absorbing system

Patented impact-absorbing system

A patented impact-absorbing system is provided:

- This exclusive feature allows the wing decks to move rearward and inward when contacting obstructions such as trees, curbs, or other solid objects to prevent damage.

- Mowers are safety certified (meaning that mowers have been evaluated by the manufacturer [John Deere Turf Care] and conform to American National Standards Institute [ANSI] B71.4 Safety Certification Specifications for Commercial Turf Care Equipment).

Isolated deck motor design

Isolated deck motor design

Isolated deck motor designThe isolated deck motor design consists of three cast-iron mounting structures for the deck motors. Rubber isolators that are similar to engine mount isolators are located between the castings and the deck shell brackets.

The rubber isolators allow the castings to flex relative to the deck shell. The addition of the isolators stops the vibration path between the hydraulic motor and the deck shell, thus preventing the amplification of sound by the deck shell.

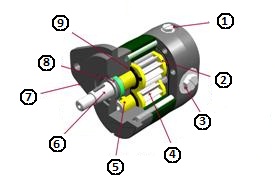

Deck motors

Deck motor

Deck motor D Series deck motor

D Series deck motor- Radial case drain

- Pressure balanced bronze-on-steel thrust plates

- Flexible configuration of shaft, flange, and ports

- One-piece steel gears with 12-tooth profile

- Heavy-duty, low-friction sleeve bearings

- Integrated dust protector

- High-strength ductile iron body and covers

- High-temperature Viton® rubber shaft seals

- Figure 8 monolithic high-temp load seals

The deck motors are capable of withstanding high pressure requirements for all-day mowing. Motors have Viton seals, which can withstand higher hydraulic temperatures. The motor contains a dust seal to help eliminate debris from entering into the hydraulic connections.

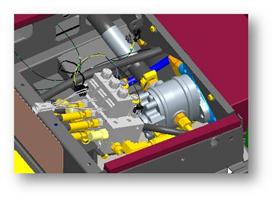

Lift valve

Lift valve

Lift valveThe lift valve controls the cylinders that lift and lower the decks. It also controls the axial piston deck-motor pump (turns it on and off).

Mow valve

Mow valve

Mow valveThe mow valve controls the hydraulic flow to the wing deck circuits.

Mower mulch kit available

WAM mulch kit illustration

WAM mulch kit illustration WAM mulch kit illustration

WAM mulch kit illustrationA mulch kit is available as an attachment for field conversion. The mulch kit includes unique mulch blades, baffles, and a deflector shield to produce smaller clippings, which decompose faster than un-mulched clippings. Operators should follow the one-third rule when mulching grass.

This mulch kit also does an excellent job when mulching leaves.

BTC10335 TriCycler Mulching Kit

NOTE: Applicable for serial numbers starting with 1TC1600TPBT100007 and higher, model year 2012 and newer.

Viton is a trademark of The Chemours Company.

Specifications

Compare the specifications of up to 4 models

| Key Specs | 1600-wide-area-mower Current Model |

|---|---|

| Engine Manufacturer/model | 4TNV86CT-DJWM (T4) |

| Engine Power | Gross power SAE J1995 at 3,000 rpm, PS 60 hp 44 kW |

| Fuel tank capacity | 22 U.S. gal./hr 83.3 L |

| Mower deck Size | 62, 94, 128 in. 157, 239, 325 cm |

| Blade tip speed | 13,000 fpm 3,962 m/min |

| Transmission | Hydrostatic |

| Speed range | 0-15 mph 0-24 km/h |

| Drive tires | 26x12-12 |

| Caster wheels | Four, 11x4-5, flat-free Two, 11x4-5, flat-free |

| Warranty | 24 monhs |

| Engine | |

| Manufacturer/model | |

| Model | 4TNV86CT-DJWM (T4) |

| Displacement | 127.6 cu in. 2.091 L 2,091 cc |

| Bore and stroke | 3.4x3.5 in. 86x90 mm |

| Injection | Direct |

| Starting aid | Engine glow plug |

| Cylinders | Four |

| Cycle | Four |

| Power | Gross power SAE J1995 at 3,000 rpm, PS 60 hp 44 kW |

| Rated engine speed | 3,000 rpm |

| Operating range | With isochronous governor 1,400-3,030 rpm |

| Lubrication | Pressurized by lobe-style pump |

| Oil filter | Spin-on |

| Cooling | Liquid-cooled water centrifugal |

| Cooling system capacity | 2.5 U.S. gal. 7.5 L |

| Crankcase capacity | 6.1 U.S. qt 5.8 L |

| Compression ratio | 19:01 |

| Operating torque (net continuous @ 3000 rpm) | 103 lb-ft 140 Nm |

| Max Torque per SAE J1349 (net continuous) | 117.3 lb-ft 159 Nm |

| Air cleaner | Dual element, dry type |

| Air restriction indicator | Standard, progressive type |

| Engine shutoff | Key |

| Radiator location | Rear mounted |

| Radiator fins per inch | 10 fins per inch |

| Horsepower (net intermittent) | |

| Fuel system | |

| Fuel type | Diesel |

| Fuel transfer pump | Electric |

| Fuel filter | Replaceable, spin-on type |

| Water separator | Replaceable, 100-mesh element |

| Cold start device | Increased timing for better cold starting |

| Fuel tank capacity | 22 U.S. gal. 83.3 L |

| Fuel pump type | Mechanical |

| Fuel neck opening | 3 in. 7.6 cm |

| Fuel tank location | Left side of the machine |

| Self bleeding | System is self-bleeding because of the electric fuel transfer pump |

| Fuel consumption | |

| Full load | 3.33 U.S. gal./hr 12.7 L/hr |

| One-half load | 1.93 U.S. gal./hr 7.31 L/hr |

| Implement lift | |

| Type | Hydraulic, open center |

| Lift cylinders | Bore 2 in. 50.8 mm |

| Pump | Gear |

| Electrical | |

| Charging system | Automotive type |

| Alternator | 75 amp |

| Battery voltage | 12 V |

| Battery cold crank amps | 675 CCA |

| Starter size | 1.9 hp 1.4 kW |

| Hydraulic system | |

| Traction drive pump | Displacement, axial piston pump, 3 cu in. 49 cc |

| Motor | Displacement, axial piston pump, 2 cu in. 33 cc |

| Type | Closed loop, hydrostatic |

| Steering relief | 1,087 psi |

| Implement relief | 1,600 psi |

| Hydraulic reservoir capacity | 14 U.S. gal. 53 L |

| Drivetrain | |

| Transmission | Hydrostatic |

| Transaxle type | Dual range |

| Transaxle | Tuff Torque (Kanzaki) |

| 4 wheel drive | On demand or full time |

| 4 wheel drive type | Mechanical rear-wheel drive |

| Differential lock | Mechanical, foot activated |

| Final drive | Planetary |

| Brakes | |

| Type | Internal, wet disc |

| Steering brakes | Standard |

| Parking brakes | Hand brake |

| Travel speed | |

| Speed range | 0-15 mph 0-24 km/h |

| Low forward speed | 0-9 mph 0-14.5 km/h |

| High forward speed | 0-15 mph 0-24 km/h |

| Low reverse speed | 0-4.5 mph 0-7.2 km/h |

| High reverse speed | 0-7.5 mph 0-12 km/h |

| Sound level (without cab) | |

| With deck | 94 dBA |

| Without deck | 89 dBA |

| Frame | |

| Frame type | Welded, tubular steel |

| Thickness | 11 gauge 0.12 in. 3 mm |

| Steering | |

| Type | Power, hydrostatic |

| Tilt steering wheel | Standard |

| Turns lock-to-lock | 2.5 |

| Turning radius | 39 in. 99 cm |

| Operator station | |

| Seat | Adjustment positions Multi Armrests Yes, adjustable Air-ride suspension seat, adjustable, deluxe, high-backed, back angle adjustment, lumbar adjustment, standard armrests |

| Safety | Safety interlock and operator presence system |

| Tires | |

| Drive tires | Pressure 30 psi , 206.8 kPa (front) 28 psi, 193.1 kPa (rear) 26x12-12 |

| Steering tires (rear) | 18x9.5-8 |

| Tread | Multi-trac |

| Ply rating | 6 PR (both) |

| Dimensions | |

| Length (with deck) | 132 in. 335 cm |

| Wheel base | 60 in. 152 cm |

| Tread width | 52 in. 131 cm |

| Width with decks down | 134 in. 340 cm |

| Height with ROPS | ROPS up, 98 in. 249 cm ROPS down, 74 in. 188 cm With four-post canopy ROPS, 82 in. 208 cm |

| Transport width | 84 in. 213 cm |

| Ground clearance | 6.5 in. 16.5 cm |

| Uncut circle of grass w/o brakes | |

| Vehicle weight | 4,173 lb 1,892.8 kg |

| Machine weight without the deck | 3,264 lb 1,474.2 kg |

| ROPS | |

| Controls | |

| Throttle | Hand |

| Forward/reverse | Two-pedal |

| Mower lift | Three two-function switches |

| Park brake | Foot pedal/disk |

| Indicator lights | Engine air heater, oil pressure light, engine temperature light, fuel gauge, hydraulic oil temperature light |

| PTO engagement | Type Hydraulic, independent Electric solenoid switch |

| PTO engagement/disengagement | Electric solenoid |

| Deck drive pump | Displacement, axial piston pump, 2.48 cu in. 40.6 cc |

| Deck motor | Type Hydraulic, open center, closed loop Displacement, gear motor, 2.5 cu in. 41 cc |

| Circuit | Series |

| Mower decks | |

| Deck drive type | Hydraulic, closed loop |

| Spindles | Heat treated, diameter, 1 in. 2.54 cm |

| Spindle bearings greaseable | Yes |

| Energy-absorbing wing decks | Yes |

| Deck circuit | Series |

| Blade drive | C-section, V-belt |

| Size | 62, 94, 128 in. 157, 239, 325 cm |

| Center deck cutting width | 62 in. 157 cm |

| Wing deck cutting width | 42 in. 107 cm |

| Transport lock | Standard |

| Discharge | Rear |

| Deck construction | Fabricated steel |

| Deck thickness | 7 gauge 0.18 in. 4.6 mm |

| Height-of-cut range | 1-5.5 in. 2.5-13.9 cm |

| Wing deck float | Up (while maintaining PTO engagement) 45 degrees Down (while maintaining PTO engagement) 20 degrees |

| Mowing rate | |

| Anti-scalp rollers | |

| Type | Flat-free |

| Wing deck caster wheels | Four, 11x4-5, flat-free |

| Front deck caster wheels | Two, 11x4-5, flat-free |

| Blades | |

| Total mower blades | Seven, three center and two each side |

| Blade length | 22 in. 55.88 cm |

| Blade width | 2.5 in. 6.35 cm |

| Blade thickness | 0.312 in. 0.79 cm |

| Blade tip speed | 13,000 fpm 3,962 m/min |

| Interchangeable mower blades between all decks | Yes |

| Buyer's notes | |

| Warranty | 24 months |

| Certification | ANSI B71.4 |

Accessories and Attachments

Lighting

This light kit signals that the unit is approaching. The light is positioned on top of the canopy or on the rollover protective structure (ROPS) with a breakaway bracket. This ensures that if struck, the light will not break, but move out of the way.

NOTE: Applicable for serial numbers:

- BUC10062 - for wide-area mowers with serial numbers 500,001 and higher.

- TCB11580 - for wide-area mowers with serial numbers 090,001 to 500,000.

- TCB10353 (discontinued) - for wide-area mowers with serial numbers 090,000 and lower.

The road light kit is for use when transporting the machine.

NOTE: Requires the work light kit to complete. Includes two combination turn signals/warning flashers/taillights, mounting brackets, a wiring harness, and a turn signal switch. Applicable for serial numbers:

- BUC10063 - for widearea mowers with serial numbers 500,001 and higher.

- TCB11701 - for widearea mowers with serial numbers 090,001 to 500,000.

- TCB10582 (discontinued) - for widearea mowers with serial numbers 090,000 and lower.

This front light kit allows operating mower during twilight hours for increased productivity.

NOTE: Includes four lights, mounting brackets, wiring harness, and on/off switch. Applicable for serial numbers:

- BUC10064 - for widearea mowers with serial numbers 500,001 and higher.

- TCB11581 - for widearea mowers with serial numbers 090,001 to 500,000.

- TCB10583 (discontinued) - for widearea mowers with serial numbers 090,000 and lower.

model year 2010 and earlier wide-area mowers, wiring harness part number TCA13797 is not part of this kit and must be ordered separately.

Miscellaneous

SMV decal

SMV decalThis warning sign is used to indicate that the unit is a slow-moving vehicle.

Mulch Kits

WAM mulch kit illustration

WAM mulch kit illustration WAM mulch kit illustration

WAM mulch kit illustrationA mulch kit is available as an attachment for field conversion. It includes unique mulch blades, baffles, and a deflector shield to produce smaller clippings, which decompose faster than un-mulched clippings. Operators should follow the one-third rule when mulching grass. This mulch kit also does an excellent job when mulching leaves.

TCB10507 TriCycler mulching kit - applicable for serial numbers 1TC1600TPBT100006 and lower, model year 2011 and older.

BTC10335 TriCycler mulching kit - applicable for serial numbers 1TC1600TPBT100007 and higher, model year 2012 and newer.

- NOTE: Includes mulching blades, baffles, and deflector shields for center and wing mower decks. Please also note that machine serial number determines which bundle number is required. These kits are not interchangeable between production ranges.

Wheels and Tires

Semi-pneumatic tires provide multiple benefits:

- Look and perform like a rubber air-filled tire

- Reduced downtime

- Reduced maintenance time and expense

- No need to worry about inflating caster tires

- Reduced caster tires rolling off of the rim

- Never need air maintenance, nor will they become flat when punctured, making them truly flat-free

Reviews

1 reviews

- Filter

- Star Rating

- Value

- Quality

© 2024 Valley Plains Equipment LLC - Powered By